Protecting Concrete with Anti-Carbonation Coatings

24th July 2019

Concrete plays a key role in the development of aesthetically pleasing structures due to its strength, flexibility and durability. However, concrete structures deteriorate with time and this deterioration is much faster in environments associated with the combination of high humidity, chlorides and CO2 in the surrounding atmosphere.

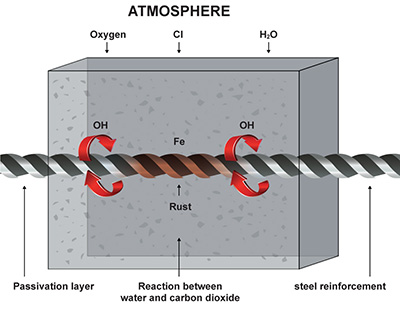

Moisture and deleterious substances such as chloride ions, CO2 and other chemicals ingress through the pores of the concrete, mainly via process of diffusion, which initiates the corrosion process and subsequently corrodes the steel reinforcement within the concrete matrix. If not mitigated or rectified in a timely manner this process will ultimately damage the reinforced concrete structure. The degree of porosity of the concrete is an influencing factor as to how susceptible it is to staining as well as its vulnerability to acid attack resulting in surface wear and dusting. A dense concrete with a design mix formula using a low water to cement ratio alone will not prevent this deterioration.

Carbonation Process

Structural integrity is heavily compromised by carbonation of concrete; most common forms of deterioration of structural concrete used in building and infrastructure are due to carbonation of concrete. Moreover, if the concrete structures are untreated they are highly vulnerable to ingress of chlorides (mainly through water), which leads to corrosion of reinforcement by incipient anode formation.

Carbonation is a natural process, enhanced in heavily polluted atmospheres, and is virtually impossible to avoid in unprotected concrete. The carbonation process begins as soon as the concrete is exposed to external elements, when carbon dioxide from the atmosphere reacts with the concrete, leading to a loss of alkalinity and subsequent corrosion of the reinforcing steel. There is a requirement in AS3600 for any area within 3km of industries that discharge atmospheric pollutant to be given an increased exposure classification.

Carbonation is a natural process, enhanced in heavily polluted atmospheres, and is virtually impossible to avoid in unprotected concrete. The carbonation process begins as soon as the concrete is exposed to external elements, when carbon dioxide from the atmosphere reacts with the concrete, leading to a loss of alkalinity and subsequent corrosion of the reinforcing steel. There is a requirement in AS3600 for any area within 3km of industries that discharge atmospheric pollutant to be given an increased exposure classification.

The fast rate of deterioration and the high cost of repair, rehabilitation, and replacement of concrete structures have become major issues in infrastructure asset management. Additionally, selection of remedial action for aging/deteriorating infrastructure and designing new projects with sustainability objectives are major challenges faced by many asset managers and designers of civil infrastructure.

Protecting Concrete from Carbonation

The carbonation of concrete is a slow and predictable process, and can be combated by specially formulated anti-carbonation coatings, which can effectively arrest carbonation, enhancing the life of the structure and avoiding costly remedial treatment in its lifespan.

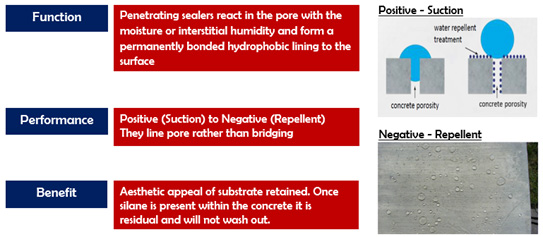

Protective treatment for atmospherically exposed concrete is a two-part process, using hydrophobic impregnants as a primer, and a highly elastomeric anti carbonation protective coating. This system provides excellent elongation and recovery, low dirt pick-up, resistance to aggressive elements, UV light and rain, enhancing the structural life of the asset.

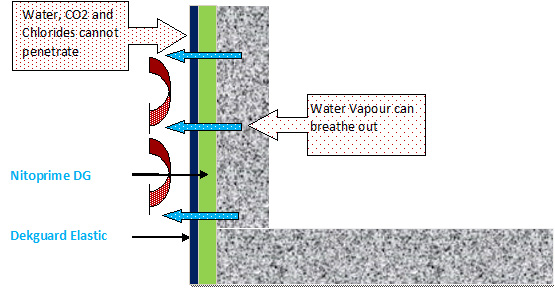

Fosroc ANZ offers high-performance anti-carbonation coatings to provide ultimate protection against the ingress of carbon dioxide, oxygen, and water, whilst allowing damp substrates to breathe without blistering. The Fosroc Dekguard Elastic system is a a high-build formulation, comprising a single component penetrating silane-siloxane primer and a single component elastomeric pigmented coating, both ready for immediate site use.

Primer: Nitoprime DG – hydrophobic impregnations

The stabilising primer (Nitoprime DG) is reactive and capable of producing a chemically-bound hydrophobic barrier, thus inhibiting the passage of water and water-borne contaminants. A thin surface film is produced which consolidates and stabilises porous substrates.

Protective treatment: Dekguard Elastic – film-forming protective coating

Dekguard Elastic is an elastomeric, water-based protective coating based on a special acrylic polymer that provides excellent elongation and recovery, low dirt pick-up, and resistance to aggressive elements, UV light, and rain.

- Thick and tough film enhancing chemical and wear resistance, reducing concrete dusting and staining

- Coating bridges hairline cracks, which are potential sources of water & deleterious chemical penetration

- Due to elastic properties, they are able to accommodate the thermal cracks on the substrate.

- Keeps the substrate clean, preventing the penetration of contaminants.

- Resistance to aggressive elements, UV light, and rain.

To learn more about Nitoprime DG, visit our product information page, here

For further information about Dekguard Elastic, visit our product information page, here, and/or take a look at this case study, recently featured on our LinkedIn page - Dekguard Elastic Case Study

Privacy Collection Statement

Concrete Plus Limited (NZBN 9429033691282) ("Concrete Plus") is a is a wholly owned subsidiary of DuluxGroup Limited. The terms "we", "us", "our" refer to the company and any of our affiliated companies.

Your privacy is important to us: Concrete Plus will use the information you submit and may disclose it to third parties to respond to your enquiry. Concrete Plus (and its marketing and communications agencies on its behalf) may also use your name and contact details to send you information for these purposes. Concrete Plus may disclose the information to contractors, market research organisations, marketing and communications agencies and related bodies corporate for this purpose. If you do not provide the personal information requested, we will not be able to fulfil your request. We may also exchange your personal information with other related companies and our service providers, such as delivery companies and technology providers.Please refer to our Privacy Policy, available on our website (www.concreteplus.co.nz/privacy-policy/) or on request. It contains further details about: (i) the personal information we collect; (ii) what we do with it; (iii) where we send it; (iv) how you can access and correct it; (v) how you can lodge a privacy complaint regarding the handling of your personal information; (vi) how we handle those complaints; (vii) online privacy; and (viii) the types of service providers we use.

If you have any questions regarding the way Concrete Plus handles your personal information or wish to seek access to, or correct, personal information we hold about you, please contact our Privacy Officer via privacy@duluxgroup.com.au or call +613 9263 5678.